Customer Results

Real deployments showing measurable outcomes.

Savings and timelines vary by site conditions and staffing model.

Estimated $216,000/year saved

Challenge

Guards manually logged every vehicle (photos + WhatsApp), creating delays, inconsistency, and high staffing costs across 24/7 coverage.

Deployment snapshot

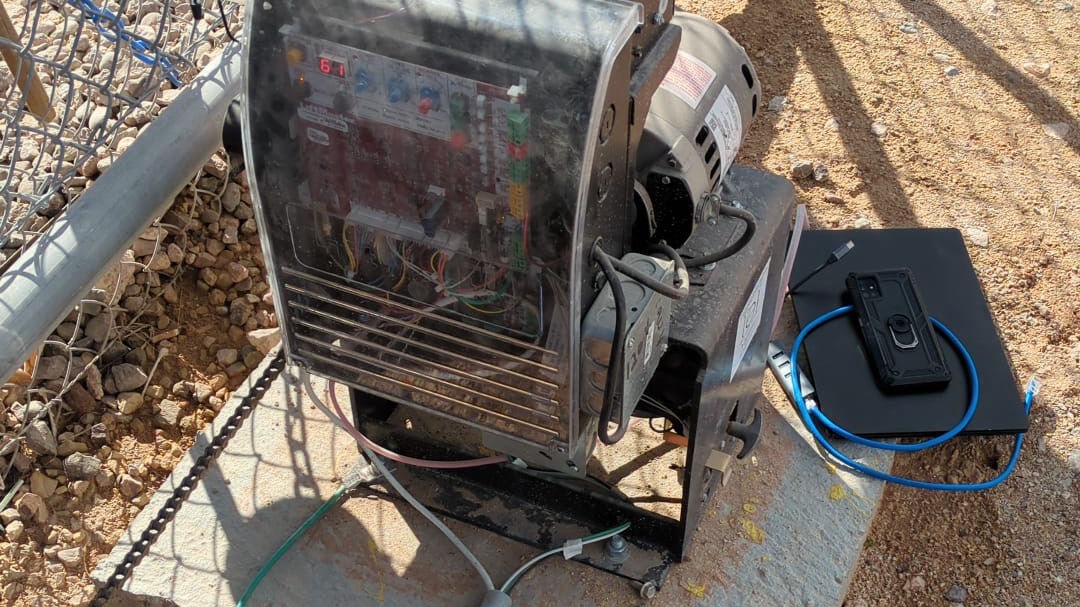

• industrial site

• bi-directional entrance

• harsh conditions

• deployed without reconstruction

What we deployed

GateGuardX automated LPR access connected to the existing gate controller. Each crossing is logged with timestamp + photo proof, searchable and exportable instantly.

Outcome

3–4 gate roles removed from gate duties

~$18,000/month estimated staffing savings

ROI in ~60 days

Reliable reads, even on damaged and dirty plates

Audit-ready logs with photo proof

Savings estimate based on customer staffing model and fully-loaded labor costs.

Includes the full workflow, site setup, and the ROI math behind the savings estimate.

How results are measured

Results are measured using system event logs (entries/exits), photo-verified audit trails, and deployment configuration records.

Savings estimates are based on the customer’s staffing model and fully-loaded labor cost assumptions. Details available on request.

Testimonials

What site operators say

"I recommend GateGuardX to organizations that need reliable access control with auditable event tracking."

CIO, Fleet Logistics Firm

“The gate now allows access seamlessly, eliminating manual checks and reducing human error while improving traffic flow in and out of the yard.”

IT Director, U.S. Oilfield Services Company

“GateGuardX significantly improved our security posture and day-to-day operational efficiency.”

Operations Manager, Fleet Logistics Firm

Mixed Gates + Mixed Cameras — Unified Under One System

Challenge

A multi-site operator had grown over time and ended up with a patchwork setup: different gate types, different camera models, and different local “workarounds” at each site. Each location had its own process for granting access, handling exceptions, and investigating incidents—making audits messy and operations inconsistent.

Deployment snapshot

• multi-site operator

• mixed gate types (swing + sliding + barrier arms)

• mixed IP cameras

• kept existing gates/cameras where usable

• central rules + alerts (one set across locations)

• one dashboard across all sites

What we deployed

GateGuardX was installed on top of the existing infrastructure: connected to each gate’s control board (dry-contact), integrated the current camera views where usable, and added only the required GateGuardX hardware kit (controller + Mini-PC) to standardize processing and decision logic. Access rules, plate lists, and alerts were configured centrally and applied consistently across locations.

Outcome

All sites managed from a single dashboard

Standardized access rules everywhere

Central alerts for denials and anomalies

No rip-and-replace (kept existing gates/cameras where usable)

Searchable, audit-ready history with photos

Solving the Rural 24/7 Staffing Problem

Challenge

A manufacturing site in a remote area struggled to hire and retain staff for round-the-clock gate coverage—especially overnight. Coverage gaps created operational risk, inconsistent access decisions, and security friction.

Deployment snapshot

• remote rural facility

• hard-to-staff overnight / weekend shifts

• night shifts

• unattended rule-based access

• photo-verified audit trail (searchable events)

What we deployed

GateGuardX automated LPR access connected to the existing gate controller. Vehicles are verified against rule-based authorization, and every crossing is logged with timestamp + photo proof, making the full access history searchable and reviewable.

Outcome

24/7 operation without local staffing

Consistent access decisions, no shift variance

Full audit trail for every entry/exit

Fewer night and weekend disruptions

The “Too Close to the Road” Entrance

Challenge

Vehicles approached with minimal distance, so a single camera angle often failed under glare or plate tilt.

Deployment snapshot

• tight approach distance (short capture window)

• problem lighting (glare) + plate tilt

• 2 cameras from opposite angles

• “best-read” selection per vehicle approach

• reduced missed reads + manual overrides

What we deployed

A two-camera setup from opposing angles, so the system could use the best read available per approach.

Outcome

Consistent reads in tight approach zones

Fewer missed opens and manual overrides

Repeatable setup for similar entrances

DOT Dispute Resolved in Minutes — With 4K Exit Proof

Challenge

During a DOT-related dispute, the site needed to verify whether a vehicle was already damaged when it exited the facility. The plate photo confirmed which vehicle it was, but it didn’t reliably show the vehicle’s condition (body panels, trailer, load, and other visible details). Reconstructing the moment from scattered camera feeds and manual notes was slow and still left room for argument.

Deployment snapshot

• compliance / dispute scenario (vehicle condition at exit)

• plate proof + full-vehicle evidence needed

• context camera added (high-end 4K, detail-focused angle)

• linked evidence per event (plate + wide view)

• fast investigation workflow (minutes, not hours)

What we deployed

Alongside the plate capture, we added a strategically placed context camera—typically a high-end 4K camera—aimed specifically to capture vehicle condition and identifying details at the time of exit. Each event now includes both plate proof and a wider, detail-oriented view.

Outcome

DOT dispute resolved with clear exit evidence

Investigations reduced to minutes

Full vehicle + scene proof, not just plate

Stronger accountability and deterrence

Induction Loop Failed for Light Vehicles — Camera-Based Exit Detection (No Digging)

Challenge

The site relied on an induction loop to open the gate from inside the yard. But lighter vehicles often didn’t trigger the loop reliably, causing stop-and-wait situations, driver frustration, and frequent manual intervention.

Deployment snapshot

• exit lane from inside the yard

• existing induction loop (inconsistent for light vehicles)

• camera-based exit trigger (“open on any plate” rule)

• early open trigger (smooth exit flow)

• no digging / no downtime / no loop replacement

What we deployed

We configured GateGuardX to open the exit gate when it detects any vehicle with a readable license plate approaching from the inside (rule-based exit workflow). The camera-based trigger activates before the vehicle reaches the loop, so vehicles don’t have to stop or “hunt” for the sensor.

Outcome

Reliable exits for light vehicles

No digging or loop replacement

Faster flow with earlier gate opens

Fewer support calls and overrides

Time-stamped photo records preserved

Pick your goal — see the impact

Reduce gate queues (seconds add up)

See what 5–60 seconds delay per crossing really costs

Remove attendants (biggest savings)

See how one site eliminated $18,000+/month by removing attendants.